Energy Conservation and Green Energy

Energy Conservation Building Code (ECBC) for Residential Buildings

ECBC for residential buildings is being launched to help reduce domestic energy

consumption. Energy Conservation Building Code (Part I: Building Envelope Design) has

been prepared to set minimum building envelope performance standards to limit heat gains

(for hot climates) and to limit heat loss (for cold climate) as well as for ensuring adequate

natural ventilation and day lighting. The code is applicable to all residential use building

projects built on plot area ≥ 250 m.

2.

The Part I – Building Envelope Design, is the first component of the Energy Conservation

Building Code for Residential Buildings to be launched. Its introduction is to improve the

construction and design of new residential building stock, as it is being built currently and in

the near future, to significantly curtail the anticipated energy demand for comfort cooling in

times to come. This critical investment in envelope construction and design made today will

reap benefits in terms of reduced energy consumption and thereby operational costs for

owners and tenants during the lifetime of the buildings

The code is designed in a simple-to-apply format, requiring only arithmetic tabulation based

on the architectural design drawings of the residential buildings. This will be usable by

architects as well as engineers and will not require any specialized skills or simulation

software. This also enables the Code to be readily adopted in the Building Byelaws and

regulatory instruments such as Environmental Clearance for Large Projects.

In the coming years, new components will be added to the Energy Conservation Building

Code for Residential Buildings, which will address other aspects such as, Energy Efficiency

in Electro-Mechanical Equipment for Building Operation, Renewable Energy Generation,

Embodied Energy of Walling Materials and Structural Systems.

Scope of the ECBC (Residential)

The code aims at limiting heat gains/loss from building envelope and for ensuring adequate natural ventilation and day lighting.

To limit the heat gain/loss from the building envelope, the code specifies:

- Maximum value of Residential Envelope Transmittance Value (RETV) for building envelope (except roof) applicable for four climate zones, viz. Composite Climate, Hot and dry Climate, Warm-humid Climate and Temperate Climate.

- Maximum value of thermal transmittance of building envelope (except roof) for Cold Climate zone (UEnvelope, cold)

- Maximum value of thermal transmittance of roof (Uroof) for all climate zones

To ensure adequate natural ventilation, the code specifies

- Minimum Openable window-to-floor area ratio (WFRop)

To ensure adequate daylighting, the code specifies

- Minimum Visible Light Transmittance (VLT) for the non-opaque building envelope components

The code is applicable to all residential use building projects built on plot area ≥ 250 m2. The type of building projects includes, but not limited to:

- Group housing projects: Building unit or units constructed or to be constructed with one or more floors having more than two dwelling units having common service facilities where land is shared and commonly used by the dwelling units, and the construction is undertaken by one agency.

- Mixed Land Use Building projects: With buildings partly used for non-residential uses and partly for residential use.

- Multi-dwelling unit building on residential plots.

Electrical Safety

As far as Electrical Safety is concerned, we have regulatory framework in India. Under The Electricity Act 2003, Central Electricity Authority was formed, which promulgates the Electrical safety regulations, and are termed as Central Electricity Authority (Measures Relating To safety and Electric Supply) Regulations 2023, which are mandatory in nature and applicable to all the states and union territories.

Some of the very important Regulations which are required to be complied with while carrying out any electrical installation, LV/MV/HV are as follows:

Key Regulations

Reg. 1 (3): Scope and extent of application

These regulations shall be applicable to electrical installation including electrical plant and electric line, and the person engaged in the generation or transmission or distribution or trading or supply or use of electricity.

Reg. 3: Designated person to operate and carry out the work on electrical lines and apparatus.

- The supplier or consumer, or owner of electrical installation, owner or agent or manager of a mine, or agent of any company operating in an oil-field or owner of a drilled well in an oil-field or a contractor who has entered into a contract with a supplier or a consumer, or owner of electrical installation, owner or agent or manager of a mine, or agent of any company operating in an oil-field or owner of a drilled well in an oil-field to carry out duties incidental to the generation, transformation, transmission, conversion, distribution or use of electricity shall designate person for the purpose to operate and carry out the work on electrical lines and apparatus.

- The supplier or consumer, or owner or agent or manager of a mine, or agent of any company operating in an oil-field or the owner of a drilled well in an oil-field or a contractor referred to in sub-regulation (1) shall maintain a record, in paper or electronic form, wherein the names of the designated person and the purpose for which they are designated, shall be entered.

- No person shall be designated under sub-regulation (1) unless,-

- he possesses a certificate of competency or electrical work permit, issued by the Appropriate Government; and

- his name is entered in the register referred to in sub-regulation (2).

Reg. 4: Inspection of record of designated person

- The record maintained under sub-regulation (2) of regulation 3 shall be produced before the Electrical Inspector as and when required.

- If on inspection, the Electrical Inspector finds that the designated person does not comply with sub-regulation

- of regulation 3, he shall recommend the removal of the name of such person from the record

Reg. 5: Electrical Safety Officer

(1) All suppliers of electricity including generating companies, transmission

Companies, distribution companies or factories registered under Factories Act having a connected load of 250 kW or more, shall designate an Electrical Safety Officer for ensuring observance of

safety measures specified under these regulations in their organisation for construction, operation and

maintenance of electrical system of all generating stations, transmission lines, substations, distribution systems and supply lines.

Reg. 6 Chartered Electrical Safety Engineer

(1) The Appropriate Government shall authorise Chartered Electrical Safety Engineer from amongst persons having the qualification and experience as per the guidelines issued by the Authority to assist the owner or supplier or consumer of electrical installations for the purpose of self-certification under regulation 32 and regulation 45 of these regulations.

Safety measures for operation and maintenance of generating station. – (1) The Engineers and Supervisors engaged or appointed to operate or undertake maintenance of any part or whole of a generating station shall hold degree or diploma in Engineering relevant to the electrical installations from a recognised institute or university.

Reg. 7: Safety measures for operation and maintenance of transmission and distribution systems

- The Engineers or Supervisors engaged or appointed to operate or undertake maintenance of transmission and distribution systems shall hold degree or diploma in appropriate trade of Engineering from a recognised institute or university.

Reg. 14: General safety requirements pertaining to construction, installation, protection, operation and maintenance of electric supply lines and apparatus

- All electric supply lines and apparatus shall be of sufficient rating for power, insulation and estimated fault current and of sufficient mechanical strength, for the duty cycle which they may be required to perform under the environmental conditions of installation, and shall be constructed, installed, protected, worked and maintained in such a manner as to ensure safety of human beings, animals and property.

- Save as otherwise provided in these regulations, the relevant standards including National Electrical Code and National Building Code shall be followed to carry out the purpose of these regulations and where relevant Indian standards are not available, international standards shall be followed and in the event of any inconsistency, the provisions of these regulations shall prevail.

- The material and apparatus used shall conform to the relevant standards.

- All electrical equipment shall be installed above the Highest Flood Level and where such equipment is not possible to be installed above Highest Flood Level, it shall be ensured that there is no seepage or leakage or logging of water.

Reg. 15: Service lines and apparatus on consumer’s premises

(1) The supplier shall ensure that all electric supply lines, wires, fittings and apparatus belonging to him or under his control, up to the point of commencement of supply, which are on a consumer’s premises, are in a safe-condition and in all respects fit for supplying electricity and the supplier shall take precautions to avoid danger arising on such premises from such supply lines, wires, fittings and apparatus.

Reg. 16: Switchgear on consumer’s premises

(1) The supplier shall provide a suitable switchgear in each conductor of every service line other than an earthed or earthed neutral conductor or the earthed external conductor of a concentric cable within a consumer’s premises, in an accessible position and such switchgear shall be contained within an adequately enclosed fireproof receptacle:

Reg.17: Identification of earthed and earthed neutral conductors and position of switches and switchgear therein

Where the conductors include an earthed conductor of a two-wire system or an earthed neutral conductor of a multi-wire system or a conductor which is to be connected thereto, the following conditions shall be complied with, -

- an indication of a permanent nature shall be provided by the owner of the earthed or earthed neutral

conductor, or the conductor which is to be connected thereto, to enable such conductor to be distinguished from any live conductor and such indication shall be provided as per relevant standards, namely: –

- where the earthed or earthed neutral conductor is the property of the supplier, at or near the point of

commencement of supply;

- where a conductor forming part of a consumer’s system is to be connected to the supplier’s earthed

or earthed neutral conductor, at the point where such connection is to be made; and

- in all other cases, at a point corresponding to the point of commencement of supply.

Reg. 18: Earthed terminal on consumer’s premises

(1) The supplier shall provide and maintain on the consumer’s premises for the consumer’s use, a suitable earthed terminal in an accessible position at or near the point of commencement of supply as per relevant standards:

Reg. 19: Accessibility to bare conductors

Where bare conductors are used in a building, the owner of such conductors shall, -

- ensure that they are inaccessible to general public;

- provide in readily accessible position switches for rendering them dead whenever necessary; and

- take such other safety measures as are specified in the relevant standards.

Reg. 20: Danger Notices

The owner of every installation of voltage exceeding 250 V shall affix permanently in a conspicuous position a danger notice in Hindi or English and the local language of the district, with a sign of skull and bones of a design as per relevant standards on, -

- every motor, generator, transformer and other electrical plant and equipment together with apparatus used for controlling or regulating the same;

- all supports of overhead lines of voltage exceeding 650 V which can be easily climbed upon without the aid of ladder or special appliances; and

- luminous tube sign requiring supply, X-ray and similar high frequency installations of voltageexceeding 650 V but not exceeding 33 kV:

Reg. 21: Handling of electric supply lines and apparatus

- Before any conductor or apparatus is handled, adequate precautions shall be taken, by earthing or other suitable means, to discharge electrically such conductor or apparatus, and any adjacent conductor or apparatus if there is danger therefrom, and to prevent any conductor or apparatus from being accidentally or inadvertently electrically charged when persons are working thereon shall be followed as per the relevant standards.

- Every person who is working on an electric supply line or apparatus or both shall be provided with, –

- personal protective equipment, tools and devices such as rubber gloves and safety footwear suitable for working voltage, safety belts for working at height, nonconductive ladder, earthing devices of appropriate class, helmet, line tester, hand lines, voltage detector and hand tools as per the relevant standards; and

- any other device for protecting him from mechanical and electrical injury due to arc flash and such personal protective equipment, tools and devices shall conform to the relevant standards and shall always be maintained in sound working condition.

Reg 22: Supply to vehicles and cranes

Every person owning a vehicle, travelling crane, or the like to which electricity is supplied from an external source shall ensure that it is efficiently controlled by a suitable switch enabling all voltage to be cut off in one operation and, where such vehicle, travelling crane or the like runs on metal rails, the owner shall ensure that the rails are electrically continuous and earthed at multiple points to ensure equipotential.

Reg 23: Cables for portable or transportable apparatus

- Flexible cables shall not be used for portable or transportable motors, generators, transformers, rectifiers, electric drills, electric sprayers, welding sets or any other portable or transportable apparatus unless they are insulated for required voltage as per the relevant standards and adequately protected from mechanical damage.

- Where the protection is by means of metallic covering, the covering shall be in metallic connection with the frame of any such apparatus and earthed.

- The cables shall be three core type and four core type for portable and transportable apparatus working on single phase and three phase supply, respectively and the core meant to be used for earth connection shall be easily identifiable.

Reg 25: Street boxes

- Street boxes shall not contain gas pipes, and precautions shall be taken to prevent, any influx of water or gas.

- Where electric supply lines forming part of different systems pass through the same street box, they shall be readily distinguishable from one another and all electric supply lines at or in street boxes shall be adequately supported and protected so as to prevent risk of damage to or danger from adjacent electric supply lines.

- All street boxes shall be regularly inspected for the purpose of detecting the presence of gas and if any influx or accumulation is discovered, the owner shall give immediate notice to the agency or company owning gas pipeline in the neighbourhood of the street box and in cases where a street box is large enough to admit the entrance of a person therein have been placed in position, provision shall be made, -

- to ensure that any gas which may by accident have obtained access to the box shall escape before a person is allowed to enter and the box shall have provision for sufficient cross ventilation; and

- for the prevention of danger from sparking.

Reg 26: Distinction of different circuits

The owner of every generating station, substation, junction box or pillar box in which there are any circuits or apparatus, whether intended for operation at different voltages or at the same voltage, shall ensure by means of indication of a permanent nature that the respective circuits are readily distinguishable from each other.

Reg 27: Distinction of the installations having more than one feed

The owner of every installation including substation, double pole structure, four pole structure or any other structure having more than one feed, shall ensure by means of indication of a permanent nature, that the installation is readily distinguishable from other installations.

Reg 28: Accidental charging

- The owners of all circuits and apparatus shall so arrange them that there shall be no danger of any part thereof becoming accidentally charged to any voltage beyond the limits of voltage for which they are intended.

- Where alternating current and direct current circuits are installed on the same box or support, they shall be so arranged and protected that they shall not come into contact with each other.

Reg 29: Provisions applicable to protective equipment

- Fire buckets filled with clean dry sand and ready for immediate use for extinguishing fires, in addition to fire extinguishers suitable for dealing with fires, shall be conspicuously marked and kept in all generating stations, enclosed substations and enclosed switching-stations in convenient location.

- Appropriate type of fire extinguisher conforming to the relevant standards, shall be installed, maintained, periodically inspected and tested as per the relevant standards for extinguishing and controlling fire and record of such tests shall be maintained.

- Sufficient number of first-aid boxes or cupboards conspicuously marked and equipped with such contents as the State Government may specify or as per the relevant standards, shall be provided and maintained at appropriate locations in every generating station, enclosed substation, enclosed switching station.

Reg. 30: Display of instructions for resuscitation of persons suffering from electric shock

(1) Instructions, in English or Hindi and the local language of the District and where Hindi is the local language, in English and Hindi for the resuscitation of persons suffering from electric shock, shall be affixed by the owner in a conspicuous place in every generating station, enclosed substation, enclosed switching station, mines and in every factory as defined in the Factory Act, 1948 (63 of 1952) in which electricity is used and in such other premises where electricity is used as the Electrical Inspector may, by notice in writing served on the owner, direct.

Reg. 31: Precautions to be adopted by consumers, owners, occupiers, electrical contractors, electrical workmen and suppliers

(1) No electrical installation work, including additions, alterations, repairs and adjustments to existing installations, except such replacement of lamps, fans, fuses, switches, domestic appliances of voltage not exceeding 250 V and fittings as in no way alters its capacity or character, shall be carried out upon the premises of or on behalf of any consumer, supplier, owner or occupier for the purpose of supply to such consumer, supplier, owner or occupier except by an electrical contractor licenced in this behalf by the State Government and on its behalf under the direct supervision of a person holding a certificate of competency and by a person holding a permit issued or recognised by the State Government:

Reg. 32: Periodic inspection and testing of installations

- The periodic inspection and testing of installation of voltage above the notified voltage belonging to the owner or supplier or consumer, as the case may be, shall be carried out by the Electrical Inspector:

Provided that the electrical installation below or equal to the notified voltage shall be self-certified by

the owner or supplier or consumer, as the case may be.

- The periodicity of electrical inspection by the Electrical Inspector or the self-certification by the supplier, owner or consumer shall be as directed by the Appropriate Government:

Reg. 35: Precautions against leakage before connection

- The supplier shall not connect its works with the apparatus in the premises of any applicant seeking supply unless the supplier is satisfied that at the time of making the connection cause a leakage from that installation or apparatus of a magnitude detrimental to safety which shall be checked by measuring the installation’s or apparatus‟ insulation resistance as stipulated in the relevant standards.

- If the supplier declines to make a connection under the provisions of sub-regulation (1) the supplier shall convey to the applicant the reasons thereof, in writing for so declining.

Reg. 37: Supply and use of electricity

- The electricity shall not be supplied, transformed, converted, inverted or used or continued to be supplied, transformed, converted, inverted or used unless the conditions provided in sub regulations (2) to (8) are complied with.

- The following controls of requisite capacity to carry and break the current shall be installed as near as possible after the point of commencement of supply so as to be readily accessible and capable of completely isolating the supply to the installation, such equipment being in addition to any control switch installed for controlling individual circuits or apparatus, namely: –

Supplied at voltage Control

Below 11 kV. Switch fuse unit or a circuit breaker by consumers. 11 kV and above. A circuit breaker by consumers.

- In case of every transformer the following shall be provided, namely: –

-

on primary side of transformer, a linked switch with fuse or gang operated air break switch with fuse or circuit breaker of adequate capacity:

Provided that the linked switch with fuse on the primary side of the transformer may be of such

capacity as to carry the full load current and to break only the magnetising current of the transformer:

Provided further that for transformer having capacity of 1000 kVA and above, a circuit breaker shall

be provided:

Provided also that the linked switch with fuse or gang operated air break switch with fuse or circuit

breaker on the primary side of the transformer shall not be required for the unit auxiliary transformer and generator transformer.

- on the secondary side of all transformers a circuit breaker of adequate rating shall be installed:

Provided that for supplier’s transformers of capacity below 1000 kVA, a linked switch with fuse or

circuit breaker of adequate rating shall be installed on secondary side.

Reg. 38: Provisions for supply and use of electricity in multi-storeyed building more than fifteen metre in height

- The connected load and voltage of supply above which inspection is to be carried out by an Electrical Inspector for a multi-storeyed building of more than fifteen metre height shall be notified by the Appropriate Government.

- Before making an application for commencement of supply or recommencement of supply after an

installation has been disconnected for a period of six months or more, the owner or occupier of a multi-storeyed building shall give not less than thirty days notice in writing to the Electrical Inspector specifying therein the particulars of installation and the supply of electricity shall not be commenced or recommenced within this period, without the approval in writing of the Electrical Inspector.

- The following safety measures shall be provided in the multi-storeyed buildings of more than fifteen metre height and other premises such as airports, hospitals, hotels, places of entertainment, places of worship, cultural centres, stadium, academic buildings, test labs, industrial installations, installation with explosive or flammable material, railway or metro stations and other public buildings, namely: –

- the supplier or owner of the installation shall provide at the point of commencement of supply a

suitable isolating device with cut-out or breaker to operate on all phases except neutral in the three-phase, four-wire circuit and fixed in a conspicuous position at not more than 1.70 metre above the ground so as to completely isolate the supply to the building in case of emergency;

- the owner or occupier of a multi-storeyed building shall ensure that electrical installations and works inside the building are carried out and maintained in such a manner as to prevent danger due to shock and fire hazards, and the installation is carried out as per the relevant standards;

- no other service pipes and cables shall be taken through the ducts provided for laying of power cables and all ducts provided for power cables and other services shall be provided with fire barrier at each floor crossing.

- the Fire-Retardant Low Smoke and Low Halogen power cables shall be used in building of more than fifteen metre height as per relevant standards:

Provided that Halogen Free Flame Retardant power cables as per the relevant standards shall be used

in airports, hospitals and hotels irrespective of height;

- distribution of electricity to the floors shall be done using bus bar trunking system;

- lightning protection of the building shall be as per the relevant standards;

- verification of electrical wiring of the building shall be carried out as per the relevant standards; and

- electricity meter shall not be installed in the passage of staircase.

Reg. 39: Conditions applicable to installations of voltage exceeding 250 Volts

The following conditions shall be complied with where electricity of voltage above 250 V is supplied, converted, transformed or used, namely: –

- all conductors, other than those of overhead lines, shall be completely enclosed in mechanically strong metal casing or metallic covering which is electrically and mechanically continuous and adequately protected against mechanical damage unless the said conductors are accessible only to a designated person or are installed and protected so as to prevent danger:

Provided that non-metallic conduits conforming to the relevant standards may be used for installations of voltage not exceeding 650 V;

- all metal works, enclosing, supporting or associated with the installation, other than that designed to serve as a conductor shall be connected with an earthing system as per relevant standards and the provisions of regulation 43;

- every switch board shall comply with the following, namely: –

- a clear space of not less than one metre in width shall be provided in front of the switchboard;

- if there are any attachments or bare connections at the back of the switchboard, the space, if any, behind the switchboard shall be either less than twenty centimetre or more than seventy five centimetre in width, measured from the farthest protruding part of any attachment or conductor; and

- if the space behind the switchboard exceeds seventy-five centimetre in width, there shall be a

passage way from either end of the switchboard, clear to a height of 1.8 metre.

Reg. 42, Test of insulation resistance

Where any electric supply line for use at voltages not exceeding 650 V has been disconnected from a system for the purpose of addition, alteration or repair, such electric supply line shall not be reconnected to the system until the supplier or the owner has carried out the test.

Reg. 43: Connection with earth

The following conditions shall apply to the connection with earth of systems at voltage exceeding 50 V but not exceeding 650 V, namely

- neutral conductor of a three phase, four-wire system and the middle conductor of a two-phase, three-wire system shall be earthed as per the relevant standards;

- neutral conductor shall also be earthed at one or more points along the distribution system or service line in addition to any connection with earth which shall be at the consumer’s premises;

- in the case of a system comprising electric supply lines having concentric cables, the external conductor or armour of such cables shall be earthed by two separate and distinct connections with earthing system;

- in a direct current system, earthing and safety measures shall be as per the relevant standards;

(v) every building shall have protective equipotential bonding by interconnecting the exposed and extraneous conductive parts as per the relevant standards;

- the alternating current systems which are connected with the earth as provided in this regulation shall be electrically interconnected:

Provided that each connection with the earth is bonded to the metal sheathing and metallic armouring, if any, of the electric supply lines;

- the frame of every generator, stationary motor, portable motor, and the metallic parts, not intended as conductors, all transformers and any other apparatus used for regulating or controlling electricity, and all electricity consuming apparatus, of voltage exceeding 250 V but not exceeding 650 V shall be earthed by two separate and distinct connections with earth by the owner as specified in the relevant standards;

- all metal casing or metallic coverings containing or protecting any electric supply line or apparatus shall be connected with the earth and shall be so joined and connected across all junction boxes and other openings as to provide good mechanical and electrical connection throughout the length:

Provided that the conditions mentioned in this regulation shall not apply, where the supply voltage does not exceed 250 V and the apparatus consists of wall tubes or brackets, electroliers, switches, ceiling fans or other fittings, other than portable hand lamps and portable and transportable apparatus, unless provided with the earth terminal and to class-II apparatus and appliances of the relevant standards:

Provided further that where the supply voltage is not exceeding 250 V and where the installations are either new or renovated, all plug sockets shall be of the three pin type, and the third pin shall be permanently and effectively earthed;

- All earthing systems shall, –

- consist of equipotential bonding conductors capable of carrying the prospective earth fault current

without exceeding the allowable temperature limits as per relevant standards in order to maintain all noncurrent

carrying metal works reasonably at earth potential and to avoid dangerous contact potentials being

developed on such metal works;

- have earth fault loop impedance sufficiently low to permit adequate fault current for the operation of

protective device within the time stipulated in the relevant standards; and

- be mechanically strong, withstand corrosion and retain electrical continuity during the life of the

installation and all earthing systems shall be tested to ensure effective earth bonding as per the relevant standards, before the electric supply lines or apparatus are energised;

- all earthing systems belonging to the supplier shall in addition, be tested for resistance on dry day during the dry season at least once in a year;

- earth fault loop impedance shall be tested to ensure the automatic operation of the protective device and a record of every earth test made and the result thereof shall be kept by the supplier for a period of not less than two years after the day of testing and shall be available to the Electrical Inspector when required;

- earth fault loop impedance of each circuit shall be limited to a value determined by the type and current rating of the protective device used such that, on the occurrence of an earth fault, disconnection of the supply shall occur before the prospective touch voltage reaches a harmful value; and

- the neutral point of every generator and transformer shall be earthed by connecting it to the earthing system not by less than two separate and distinct connections.

Reg. 44: Residual Current Device

The use of electricity to electrical installation, shall be controlled by a residual current device to disconnect the supply having rated residual current and duration as per the relevant standards:

Provided that in domestic installation, residual current device having residual operating current not exceeding 30 milliampere shall be used:

Reg. 46: Use of electricity at voltage exceeding 650 V

- The Electrical Inspector where the supply voltage exceeds the notified voltage shall not authorise the supplier to commence supply or recommence the supply, where the supply has been discontinued for a period of six months or more, or the supplier, where the supply voltage is equal to or below the notified voltage but exceeds 650 V, shall not commence supply or recommence the supply where supply has been discontinued for a period of six months or more, to any consumer unless, –

- all conductors and apparatus situated on the premises of the consumer are so placed as to be

inaccessible except to the designated person;

-

the consumer has provided and agreed to maintain a separate building or a locked weather proof and fire proof enclosure of agreed design and location, to which the supplier at all times shall have access for the purpose of housing his apparatus and metering equipment, or where the provision for a separate building or enclosure is impracticable, the consumer has segregated the aforesaid apparatus of the supplier from any other part of his own apparatus:

Provided that the segregation shall be made by the fire walls, if the Electrical Inspector

considers it to be necessary:

Provided further that in the case of an outdoor installation the consumer shall suitably

segregate the aforesaid apparatus belonging to the supplier from his own;

- all pole type substations are constructed and maintained in accordance with regulation 52

-

Where electricity at voltage exceeding 650 V is supplied, converted, transformed or used, the owner shall, –

-

maintain safety clearances for electrical apparatus as per relevant standards specification so that

sufficient space is available for easy operation and maintenance without any hazard to the operating and maintenance personnel working near the equipment and for ensuring adequate ventilation:

Provided that in case of mines, the safety clearances for electrical apparatus to be as per relevant

mining regulations.

-

not allow any encroachment below such installation:

Provided that where the Electrical Inspector comes across any such encroachment, he shall direct

the owner to remove such encroachments;

-

maintain minimum safety working clearances specified in Schedule V for the bare conductors or

live parts of any apparatus in outdoor substations excluding overhead lines of installations of voltage

exceeding 650 V;

- ensure that the live parts of all apparatus within the reach from any position in which a person may

require to be, are suitably protected to prevent danger;

- ensure that where the transformer is used, suitable provision shall be made, either by connecting

with earth, a point of the circuit at the lower voltage or otherwise, to guard against danger by reason of the said circuit becoming accidentally charged above its normal voltage by leakage from or contact with the circuit at the higher voltage;

-

not install a substation or a switching station with apparatus having more than 2000 litre of oil in the

basement where proper oil draining arrangement cannot be provided;

-

undertake the following measures, where a substation or a switching station with oil-filled

apparatus, such as transformer, static condenser, switchgear or oil circuit breaker having more than 2000 litre of oil is installed, whether indoor or outdoors,-

- the separation wall or fire barrier walls of thickness and dimensions as specified in the relevant

standards shall be provided between the apparatuses and between the apparatus and adjacent

building if building wall adjacent to the apparatuses is not rated for four hours fire withstand rating;

-

provisions shall be made for suitable oil soak pit and where use of more than 9000 litre of oil in

any one oil tank, receptacle or chamber is involved, provision shall be made for the draining away or

removal of any oil which may leak or escape from the tank, receptacle or chamber containing the

same, and special precautions shall be taken to prevent the spread of any fire resulting from the

ignition of the oil from any cause and adequate provision shall be made for extinguishing any fire

which may occur;

-

spare oil shall not be stored in the vicinity of any oil filled equipment in any such substation or

switching station; and

-

all the transformers and switchgears shall be maintained in accordance with the maintenance

schedules prepared in accordance with the relevant standards;

- without prejudice to the above measures, undertake adequate fire detection and protection

arrangement for quenching the fire of the apparatus;

-

ensure that every transformer of 10 MVA or reactor of 10 MVAR and above rating shall be

provided with automatic fire fighting system as per relevant standards;

- undertake the following measures, where it is necessary to locate the substation, or switching station

in the basement, namely: –

- the transformer room be in the first basement at the periphery.

- the direct access to the transformer room be provided from outside and the surrounding walls

of four hours fire withstand rating be provided as per relevant standards;

- the entrances to the transformer room be provided with fire resistant doors of two hour fire

rating and the door shall always be kept closed and a notice of this effect be affixed on outer side of

the door;

- a curb of a suitable height be provided at the entrance in order to prevent the flow of oil from a

ruptured transformer into other parts of the basement;

- the cables to primary side and secondary side have sealing at all floors and wall opening of

at least two hours fire withstand rating; and

- Fire Retardant Low Smoke Low Halogen cable as per relevant standards be used;

- ensure that oil filled transformers installed indoors in other than residential or commercial buildings

are placed on the ground floor or not below the first basement;

- ensure that only dry type transformer shall be used inside the residential and commercial buildings;

-

ensure that cable trenches inside the substations and switching stations containing cables are filled with sand, pebbles or similar non-inflammable materials or completely covered with non-inflammable slabs; and

-

ensure that unless the conditions are such that all the conductors and apparatus may be made dead at the same time for the purpose of cleaning or for other work, the said conductors and apparatus shall be so arranged that these may be made dead in sections, and that work on any such section may be carried on by the person designated or appointed or engaged or permitted under these regulations without danger.

- The minimum clearances specified in Schedule VI shall be maintained for bare conductors or live parts of any high voltage direct current apparatus in outdoor substations, excluding high voltage direct current overhead lines.

- There shall not be tapping of another transmission line from the main line for 66 kV and above class of lines:

Provided that during natural calamities, tapping may be allowed to ensure emergency power supply

to affected areas till normalcy is restored.

Reg. 47: Inter-locks and protection for use of electricity at voltage exceeding 650 V

-

The owner shall ensure the following, namely: –

- isolators and the controlling circuit breakers shall be inter-locked so that the isolators cannot be

operated unless the corresponding breaker is in open position;

-

isolators and the corresponding earthing switches shall be inter-locked so that no earthing switch can be closed unless and until the corresponding isolator is in open position;

-

where two or more supplies are not intended to be operated in parallel, the respective circuit breakers or linked switches controlling the supplies shall be inter-locked to prevent possibility of any inadvertent paralleling or back feed;

-

when two or more transformers are operated in parallel, the system shall be so arranged as to trip the secondary breaker of the transformer in case the primary breaker of that transformer trips;

-

all gates or doors which provide access to live parts of an installation shall be inter-locked in such a

way that these cannot be opened unless the live parts are made dead and proper discharging and earthing of these parts shall be ensured before any person comes in close proximity of such parts; and

-

where two or more generators operate in parallel and neutral switching is adopted, inter-lock shall be provided to ensure that the generator breaker cannot be closed unless one of the neutrals is connected to the earthing system.

-

The following protection shall be provided in all systems and circuits to automatically disconnect the supply under abnormal conditions, namely: –

- over current protection to disconnect the supply automatically if the rated current of the equipment,

cable or supply line is exceeded for a time which the equipment, cable or supply line is not designed to

withstand;

-

earth fault or earth leakage protection to disconnect the supply automatically, if the earth fault current exceeds the limit of current for keeping the contact potential within the reasonable values;

-

buchholz relay, pressure relief device and winding and oil temperature protection with alarm and trip contacts shall be provided on all transformers of ratings 1000 kVA and above;

(iv) transformers of capacity 10 MVA and above shall be protected against incipient faults by differential

protection;

-

transformers of capacity 10 MVA and above shall be protected against incipient faults by differential

protection;

-

all generators with rating of 100 kVA and above shall be protected against earth fault or leakage;

-

all generators of rating 1000 kVA and above shall be protected against faults within the generator

winding using restricted earth fault protection or differential protection or by both;

-

high speed bus bar differential protection along with local breaker back up protection shall be

commissioned and shall always be available at all 132 kV and above voltage substations and switching

stations and generating stations connected with the grid:

Provided that in respect of existing 132 kV substations and switching stations having more than one

incoming feeders, the high speed bus bar differential protection along with local breaker back up protection, shall be commissioned and shall always be available; and

-

in addition to above, all electrical protection system for generating stations, substations and

transmission lines shall be as per the regulations notified by the Authority under clause (e) of sub-section (2) of section 177 of the Act.

Reg. 48: Testing, Operation and Maintenance

-

Before the approval is granted by the Electrical Inspector (under Regulation 45), the manufacturer’s test certificates shall, if required, be produced for all type, acceptance, and routine tests as per the relevant standards.

-

No new apparatus, cable or supply line of voltage exceeding 650 V shall be commissioned unless such apparatus, cable or supply line are subjected to site tests as per relevant standards.

-

No apparatus, cable or supply line of voltage exceeding 650 V which has been kept disconnected for a period of six months or more from the system for alterations or repair, shall be connected to the system until such apparatus, cable or supply line are subjected to the site tests as per relevant standards.

-

Notwithstanding the provisions of this regulation, the Electrical Inspector may require certain tests to be carried out before or after charging the installations.

-

All apparatus, cables and supply lines shall be maintained in healthy conditions and tests shall be carried out periodically as per the relevant standards.

-

Records of all tests, trippings, maintenance works and repairs of all apparatus, cables and supply lines shall be duly kept in such a way that these records can be compared with the past records.

-

It shall be the responsibility of the owner of all installations of voltage exceeding 650 V to maintain and operate the installations in a condition free from danger and as recommended by the manufacturer or by the relevant standards.

-

Failures of any 220 kV and above voltage level transformer, reactor and transmission line towers shall be reported by the owner of electrical installation, within forty eight hours of the occurrence of the failure, to the Authority and the reasons for failure and measures to be taken to avoid recurrence of failure shall be sent to the Authority within one month of the occurrence in the forms provided in Schedule VII: Provided that in case of mines and oil-fields, the failure of 10 MVA or above transformers shall be reported to Electrical Inspector of mines.

Reg. 49: Precautions to be taken against excess leakage in case of metal sheathed electric supply lines

The following precautions shall be taken in case of electric supply lines other than overhead lines, for use at voltage exceeding 650 V, namely: –

-

the conductors of the cable except the cable with thermoplastic or cross linked polyethylene, insulation without any metallic screen or armour shall be enclosed in metal sheathing which shall be electrically continuous and connected with earth, and the conductivity of the metal sheathing shall be maintained and reasonable precautions shall be taken where necessary to avoid corrosion of the sheathing;

-

the resistance of the earth connection with metallic sheath shall be kept low enough to permit the controlling circuit breaker or cut-out to operate in the event of any failure of insulation between the metallic sheath and the conductor.

Explanation. – For the purposes of this regulation;

- in the case of thermoplastic insulated and sheathed cables with metallic armour, the metallic wire or tape armour shall be considered as metal sheathing; and

- where an electric supply line as aforesaid has concentric cables and the external conductor is insulated from an outer metal sheathing and connected with earth, the external conductor may be regarded as the metal sheathing for the purposes of this regulation provided that the foregoing provisions as to conductivity are complied with.

Reg. 50: Connection with earth for apparatus exceeding 650 V

-

The entire switchyard or substation equipment and buildings including all non-current carrying metal parts associated with an installation shall be effectively earthed to an earthing system or mat which shall, –

- limit the touch and step potential to tolerable values as per relevant standards;

- limit the earth potential rise to tolerable values as per relevant standards, so as to prevent danger due to transfer of potential through ground, earth wires, cable sheath, fences, pipe lines or other such equipment; and

- maintain the resistance of the earth connection to such a value as to make operation of the protective device effective.

-

In the case of star connected system with earthed neutrals or delta connected system with earthed artificial neutral point,-

-

the neutral point of every generator and transformer shall be earthed by connecting it to the earthing

system not by less than two separate and distinct connections:

Provided that the neutral point of a generator may be connected to the earthing system through an

impedance to limit the fault current:

Provided further that in the case of multi-machine systems, neutral switching may be resorted to, for

limiting the injurious effect of harmonic current circulation in the system;

-

the generator or transformer neutral shall be earthed through a suitable impedance where an appreciable harmonic current flowing in the neutral connection causes interference with the communication circuits; and

-

in case of the delta connected system, the neutral point shall be obtained by the insertion of a earthing transformer and current limiting resistance or impedance wherever considered necessary at the commencement of such a system.

-

In case of generating stations, substations and other installations of voltage exceeding 33 kV, the system neutral earthing and protective frame earthing may be, if system design so warrants, integrated into common earthing grid provided the resistance to earth of combined mat does not cause the step and touch potential to exceed the values as per relevant standards.

-

Single phase systems of voltage exceeding 650 V shall be effectively earthed.

-

In the case of a system comprising electric supply lines having concentric cables, the external conductor shall be connected with the earth.

-

Where a supplier proposes to connect with earth an existing system for use at voltage exceeding 650 V

which has not hitherto been so connected with earth, he shall give not less than fourteen days notice in writing together with particulars of the proposed connection with earth to the telegraph authority established under the Indian Telegraph Act, 1885 (13 of 1885).

-

Where the earthing lead and earth connection are used only in connection with earthing guards laid under overhead lines of voltage exceeding 650 V but not exceeding 33 kV where they cross a telecommunication line or a railway line, and where such lines are equipped with earth leakage protective device, the earth resistance shall not exceed twenty-five ohms and the project authorities shall obtain no objection certificate from Railway Authorities and Power and Telecommunication Coordination Committee before energisation of the facilities.

-

Every earthing system belonging to either the supplier or the consumer shall be tested for its resistance to earth on a dry day during dry season not less than once in a year and records of such tests shall be maintained and produced, if so required, before the Electrical Inspector.

General conditions for transformation and control of electricity. – Where electricity of voltage exceeding 650 V is transformed, converted, regulated or otherwise controlled in substations or switching stations including outdoor substations and outdoor switching stations or in street boxes constructed underground, the following provisions shall be ensured, namely: –

-

substations and switching stations shall preferably be erected above ground, but where necessarily

constructed underground due provisions for ventilation and drainage shall be made and any space housing switchgear shall not be used for storage of any materials especially inflammable and combustible materials or refuse; and

-

-

outdoor substations except pole type substations and outdoor switching stations shall, unless the apparatus is completely enclosed in a metal covering connected with earth, the said apparatus also being connected with the system by armoured cables, be protected by fencing not less than 1.8 metre in height or other means so as to prevent access to the electric supply lines and apparatus therein by an unauthorised person and the fencing of such area shall be earthed efficiently; and

-

transformer mounting structure shall be as per the regulations notified by the Authority under clause (e) of sub-section (2) of section 177 of the Act.

Latest Technologies for Energy Conservation of Electrical Systems

Energy efficiency should be viewed as an energy reserve just like fossil fuel reserves. There is a very significant potential (15-25%) to improve industrial energy efficiency using existing, proven technologies that are cost-effective today, as well as applying new technologies. Best practices in Electrical and Thermal, along with relevant case studies, covering electrical and thermal areas are presented here:

Best Practices and Technologies in Electrical System

Case for Energy Efficient Motors

Electric motors convert electrical power into mechanical power within a motor-driven system. In industrial applications, electric motor driven systems are used for various applications such as pumping, compressed air, fans, conveyors, etc. The system approach for optimizing energy efficiency of motor-driven systems is recommended, which includes the following:

- Use of energy efficient motors;

- Selecting the driven equipment―like pumps, fans, compressors, transmissions,

- variable speed drives―right type and size, and high efficiency;

- Efficient operation of the complete system.

From the motor perspective, when buying a new motor, operating cost and not just the purchase cost should be the main consideration. In a single year, the cost of energy can be up to 10 times the purchase cost. Over the life of the motor, it is by far the most significant cost. Old motors, typically more than 15 years and operating for over 5000 hours in a year can be considered for replacement with energy-efficient motors to reduce energy costs.

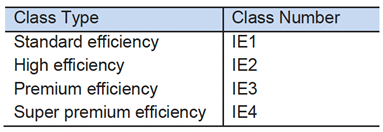

IE Classification

International Efficiency (IE) is a new trend around the world in describing the energy

efficiency of motors. The IE classes IE1 to IE4 are well developed, while the IE5 is under

preparation. The classification method allows for further improvement in the energy

efficiency of motors. The IE Classification as per IEC 60034-30-1 is shown in Table below:

IE Classes:

IE4 represents the highest energy efficiency while IE1 represents the least energy efficiency.

In other words, the higher the class number, the higher will be the motor efficiency. IE5 is to

be incorporated in the next edition of IEC 60034-30-1, with a goal to obtain an energy loss

reduction of 20% relative to IE4.

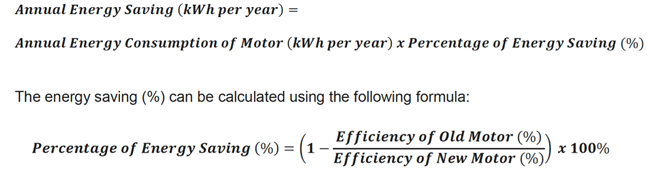

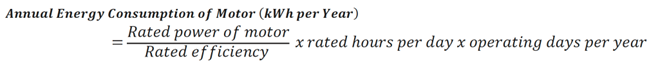

Energy Savings with Energy Efficient Motor

The annual energy saving by upgrading to more efficient motor is calculated as per the

following formula:

If the annual energy consumption of motor is not available, it can be estimated with the following formula:

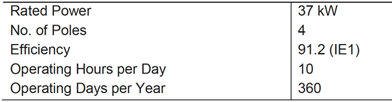

Replacing IE1 Motor with IE3 Motor

The information regarding the old motor and the operation pattern is as follows:

The annual energy consumption is calculated as follows:

Annual Energy Consumption (kWh per Year) = 37 kW/0.912 x 10 hours per day x 360 days/

year = 1,46,052 kWh

It is proposed to replace IE1 with IE3 motor as per following specifications:

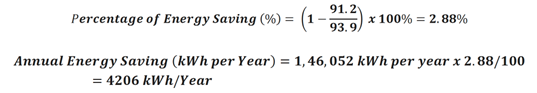

The percentage of energy-saving and the anticipated annual energy saving is calculated

below:

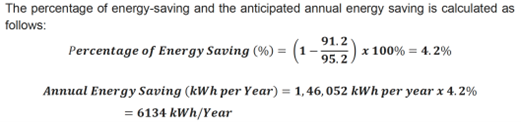

Replacing IE1 Motor with IE4 Motor

If the new motor is IE4 with following specifications, energy savings is as follows:

Variable Frequency Drive (VFD) Applications

The potential for energy saving from speed reduction depend on the characteristics of the

load being driven. There are three main types of load prevalent in industry: variable torque,

constant torque and constant power.

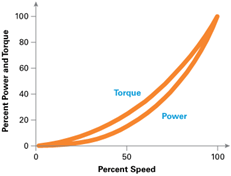

Variable Torque Load

Variable torque loads are typical of centrifugal fans and pumps and have the largest energy

saving potential. They are governed by the Affinity Laws which describe the relationship between the

speed and other variables:

- The change in flow varies in proportion to the change in speed:

Q1/Q2 = (N1/N2)

- The change in head (pressure) varies in proportion to the change in speed squared:

H1/H2 = (N1/N2)²

- The change in power varies in proportion to the change in speed cubed:

P1/P2 = (N1/N2)³

Where, Q = volumetric flow, H = head (pressure), P = power, N = speed (rpm)

Variable Torque Load

Constant Torque Load

Typical constant torque applications include conveyors, agitators, crushers, positive displacement pumps and air compressor. On constant torque loads the torque remains constant with speed and the power absorbed is directly proportional to the speed this means that the power consumed will be in direct proportion to the useful work done, for example a 50% reduction in speed will result in 50% less power being absorbed or consumed.

Although the potential energy savings from speed reductions are not as attractive as that with variable torque loads, they are still worth investigating to achieve efficient process control and energy savings.

Constant Torque Load

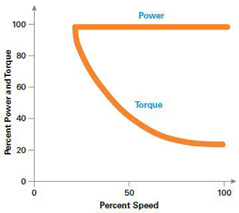

Constant Power

On constant power loads, the power absorbed is constant while the torque is inversely proportional to

the speed. The torque loading is a function of speed up to 100% operating speed. As the speed of the operation is decreased, the torque increases so that the power required remains essentially constant.

Typical applications are saws, grinders, and machine tools. The installation of VFD is not recommended for constant power applications.

Constant Power Control

VFD for Fans

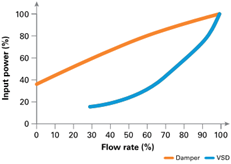

Dampers are often used to regulate the flow of fans in applications such as ventilation systems, air extract systems, industrial cooling, combustion-air control, and flue gas evacuation systems for boilers. With damper control, the input power reduces as the flow rate decreases.

If dampers are replaced with VFD control, input power is reduced much more significantly as per the cube law.

Damper Vs. VFD

Note: One limitation of VFDs is that the speed can be reduced below 30% only with caution, as the cooling capacity of the motor will be affected.

Participating in the Smart City Concepts

In India, about 31% of population living in urban areas contribute 63% of GDP. It is projected

that by 2050, 70% of the population in India will be living in the cities. Cities are already

facing problems such as high population, migration from rural areas, poor air quality,

inadequate waste management, declining quality of life, power shortage, traffic jam,

overburdened transport system and so on. In June 2015 the government launched the Smart

City Mission, with the aim of developing 100 smart cities across India. Smart cities mission

was conceived to find smarter solution to make cities sustainable i.e. meet the needs of

future generation.

There is no agreed decision on what a smart city is. It is very specific to the city, for each city

needs are different and so also the solutions. There is no one size fits all. The focus of smart

cities depend upon the pressing needs of its citizens, and where greater opportunities for

improvement lies. It also depends upon economic growth and quality of life. Hence, there are

various definitions of a smart city.

On such definition is as follows:

“A smart city uses information and communications technology to enhance its liveability,

workability, and sustainability.” - Smart Cities Council

The main objective of a smart city is to provide a clean, safe and sustainable environment to

live and work, by ensuring modern urban infrastructure and efficient use of resources. A

smart city should be green, efficient and climate resilient.

Pillars of a Smart City are

- Core Infrastructure

- Quality of Life

- Sustainable Environment

- Smart Solutions

A smart city uses available technologies to improve living conditions through access to

information about parameters that affect its inhabitants. These parameters include energy

consumption, utilities, transportation, air quality, water quality, waste management, health related

issues, education levels, employment and any other relevant information that could

potentially benefit the population. Thus, reaching the status of a fully autonomous smart city

is a long-term goal.

A city aspiring to become smart has to formulate its unique vision, mission and plan

reflecting its needs and aspirations depending upon the local context, resources and

priorities of its citizens. These may include even basic needs for example open public

spaces, more transit options, clean water, E-Governance, transparency etc. Citizens should

be engaged in the process. Local leaders may also customize ideas from around the world

to harness technology.

Two types of cities are being proposed (1) green field project i.e. city built from scratch

(example is Dhlorea, Gujarat), and (2) exiting city retrofitted with latest technology.

Centre has allocated a fund of INR 48000 Crores for this purpose. Each city would be

funded INR 100 crores for 5 years. An equal matching amount is to be contributed jointly by

the State and Urban Local Governments. Other sources of funding include infrastructure

financing institutions, external commercial borrowing, financial institutions, banks lending

institutions, direct investments and even other countries.

Key energy management component of smart cities includes the following:

- Distributed generation

- Smart grid

- Smart meters

- Demand response

- Demand response

- Energy storage

- Micro grid and virtual power plant

- Rooftop solar initiatives

- Smart LED

- Smart street lighting

- Energy harvesting

- Energy-efficient and adaptive construction designs, technologies and standards

- Smart equipment and appliances

- Advanced HVAC

- Building retrofits

One example of energy-related application in smart cities is the popular ‘Smart Street

Lighting’. Street lighting projects are a popular because of their enormous potential to deliver

a quick return on investment. Smart streetlights can save 50% to 70% of energy cost by

dimming lighting when activity is low. Networked LED lights can provide not only energy

savings but information about outages or other anomalies in the lighting network. These

lights are interconnected and also communicate with video cameras, parking sensors,

environmental sensors, weather sensors.

Smart Transportation

As per a World Bank study, by 2031, some 600 million people are expected to live in India's

cities. However, only about 20 Indian cities with populations over 500,000 have any kind of

organized public transport systems. In fact, the share of public transport in large Indian cities

is decreasing over the years. Furthermore, India's accident and fatality rates are among the

highest in the world, mainly affecting the poor and vulnerable who do not have their own

means of transportation.

Smart transportation includes the use of several technologies, such as car navigation; traffic

signal control systems; container management systems; automatic number plate recognition

or speed cameras to monitor vehicle activities, such as security CCTV systems; and to more

advanced applications that integrate live data and feedback from a number of sources.

Some of the technologies relevant for Smart Transportation include the following:

- Bicycle sharing systems: A bicycle sharing system, public bicycle system, or bike share

scheme, is a service in which bicycles are made available for shared use to individuals on a

very short-term basis. For many systems, smart phone mapping apps show nearby stations.

how many bikes and how many open docks are available at each station, increasing

convenience and green commuting for commuters.

- Dynamic carpooling: Carpooling applications link drivers and passengers in

real-time, thus enabling dynamic carpooling. Drivers wishing to profit from their journeys can

find people situated on the same route via a smartphone app and vice versa.

- GPS-based tracking and route information of public transport: Advanced vehicle

tracking solutions enhance operations and optimise public transportation and ridership.

These solutions offer real-time GPS tracking from mobile devices thereby increasing the

reliability of public transportation.

- Road user charging: Road user charges are direct charges levied for the use of roads,

including road tolls, distance or time-based fees, congestion charges and charges designed

to discourage use of certain classes of vehicles, fuel sources or more polluting vehicles.

These charges help to reduce peak hour travel and associated traffic congestion or other

social and environmental negative impacts associated with road travel such as air pollution,

greenhouse gas emissions.

- Single fare cards: Single fare card for fare payment for the various participating public

transportation systems. The cards can be recharged by mobile applications/internet/retail

outlets. The same cards could also be used for street parking.

- Smart parking: A smart parking leverages parking sensors, cameras, smart parking solution

to provide efficient use of on street and off street parking spaces.

- Smart toll: Smart toll leverages technology like number plate detection, RFID (Radio

Frequency Identification), etc. to charge toll fees to user account so that vehicles do not

have to wait at toll gates on national highway.

- Smart traffic lights: Smart traffic lights leverages technology to sense traffic condition and

tune traffic lights which enable smooth flow of traffic.

- Electric vehicles: Support electricity and renewable energy operated cars with the required

infrastructure, such as plug-in infrastructure for Electric Vehicles (EVs) and integration with

grid.